Cummins Aftertreatment System Training

Cummins aftertreatment system training. This course will provide participants with an understanding and knowledge of the IMO TIII HUG Aftertreatment System. Go to Play Store on your Android device. The system is designed to operate properly in cold climates.

Service and active regenerations will be observed using the scan tool. Exhaust Gas Recirculation EGR Variable Geometry Turbocharging VGT Fuel and Control Systems. At the end of the course take the quiz and you will then have the option to print a personalized certificate to.

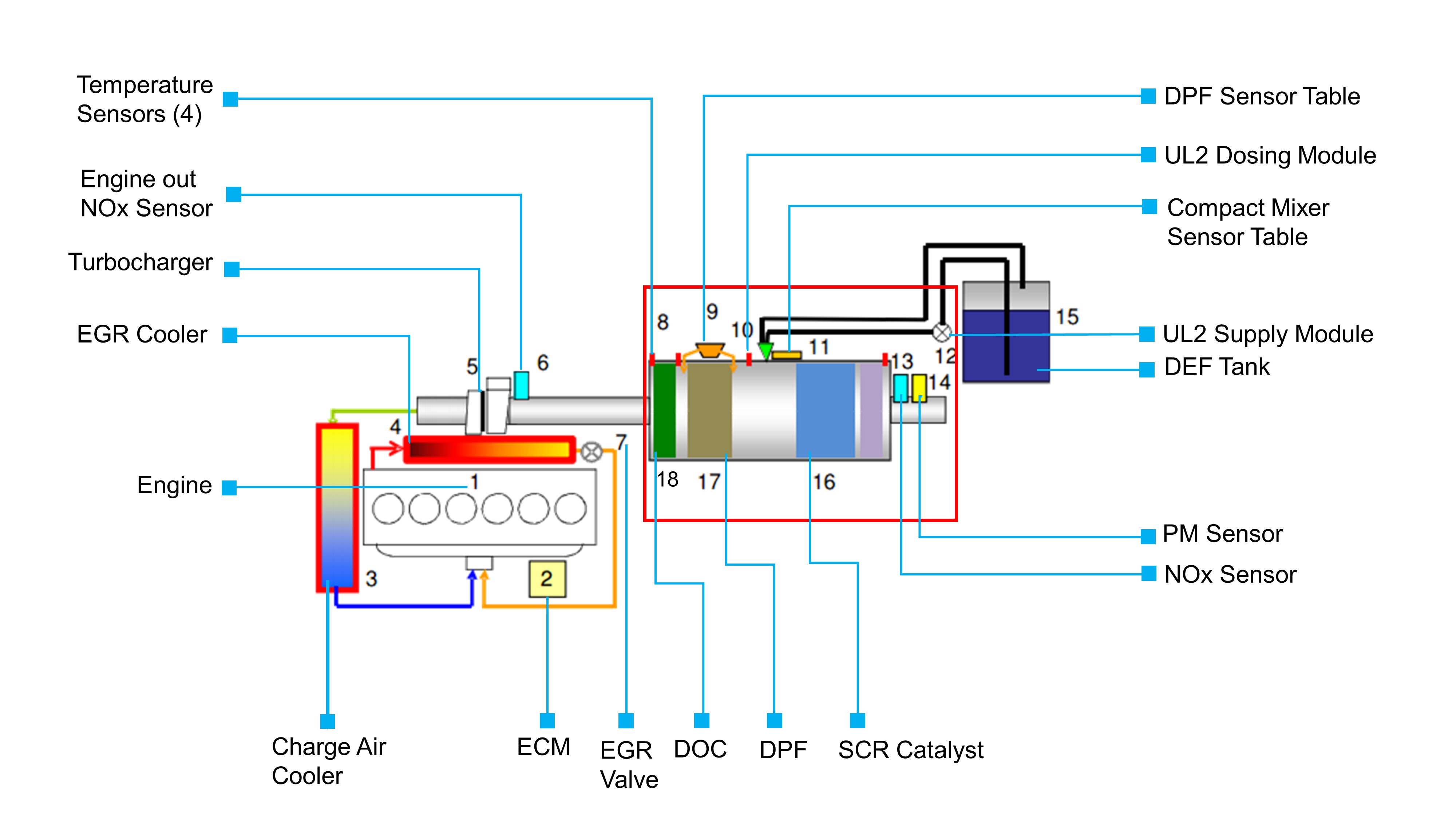

Cummins Service Technicians Distributor DFSE Commissioning Engineers Customer Technicians Service Personnel. Maintains industry-leading fuel economy Diesel Exhaust Fluid DEF usage approximately 3-4 of fuel usage Cummins Selective Catalytic Reduction SCR Catalyst Converts NOx into. After delivering nearly 100 training courses over the last 4 years VieTech has identified and packaged the essential High-Pressure Common Rail Fuel system testing tools for Cummins engines.

The listener will learn about Fuel Economy Load-Based Speed Control Gear-Down Protection the Cummins Aftertreatment System and the balance between Power and Performance - all in a lively fun manner. Electronic Controls SwitchesLamps and DatalinksCAN Bus. The DEF line from the tank to the doser will be heated by temperature controlled electrical heat tape.

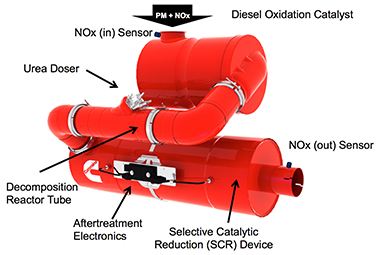

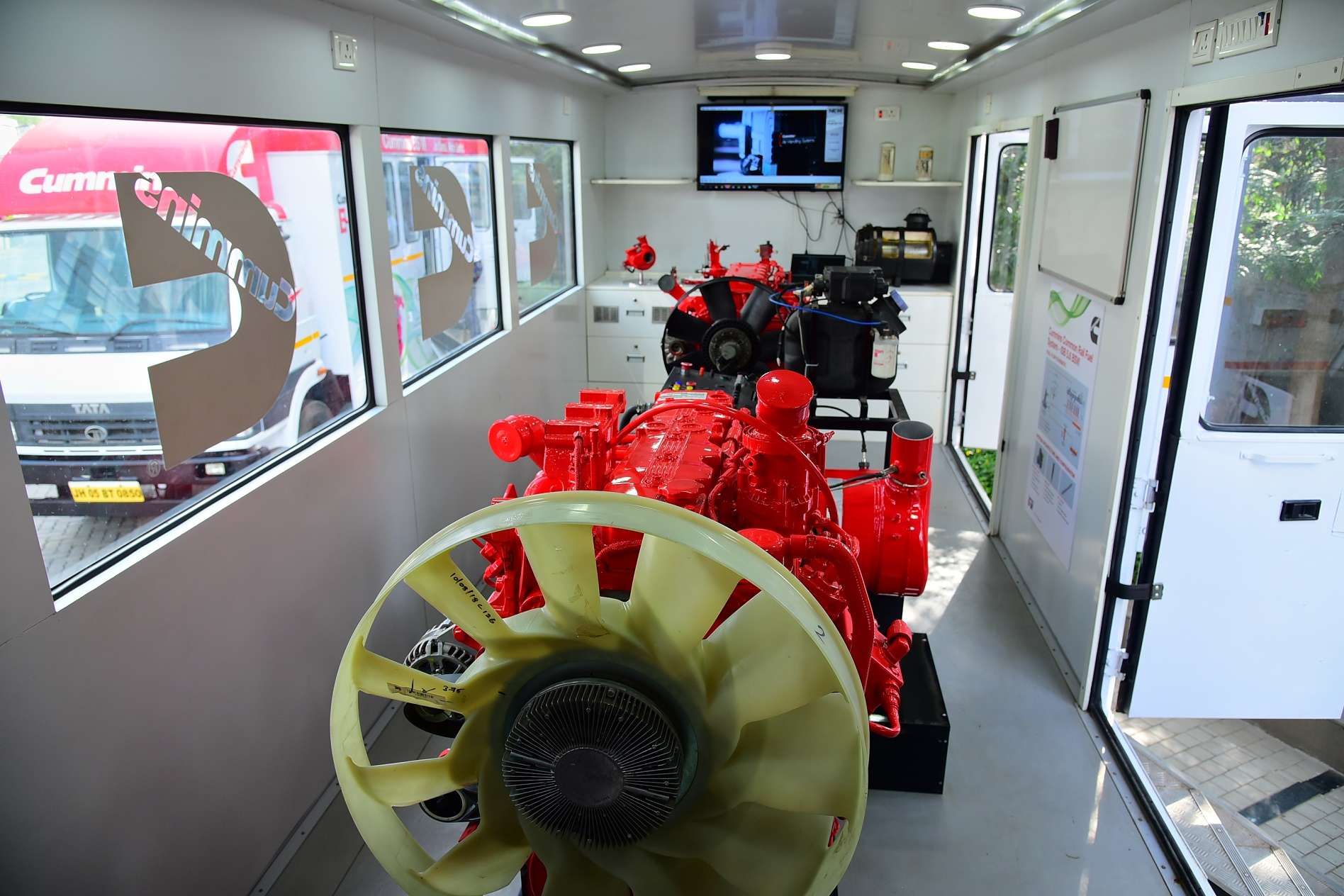

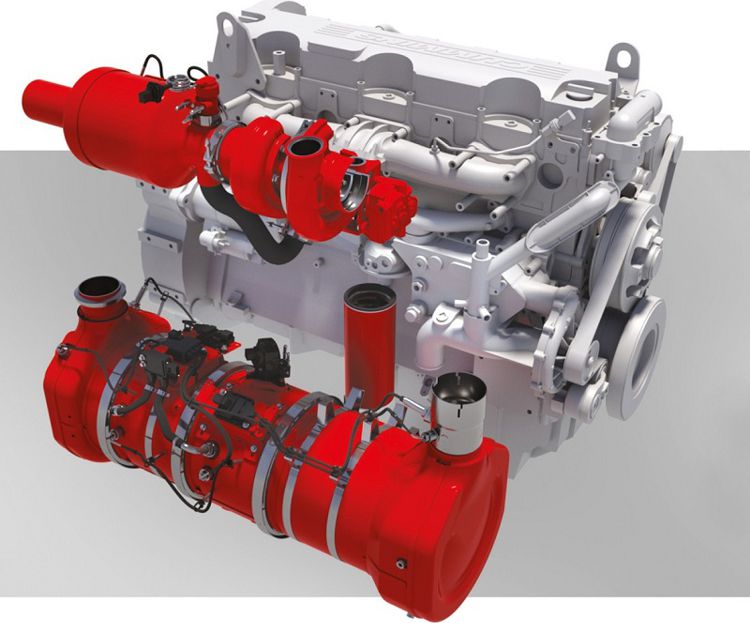

Cummins Diesel Aftertreatment Emissions Systems Virtual Class. The aftertreatment system will be discussed and each component will be taught on operation and diagnosis. In other words it is a device that cleans exhaust gases to ensure the engines meet emission regulations.

With a decade of experience with oxidation catalysts particulate filters and SCR technology our aftertreatment systems help optimize your. Our factory qualified instructors are dedicated to providing excellence quality. Vehicle Specing Basics - Cummins Online Training New for 2020.

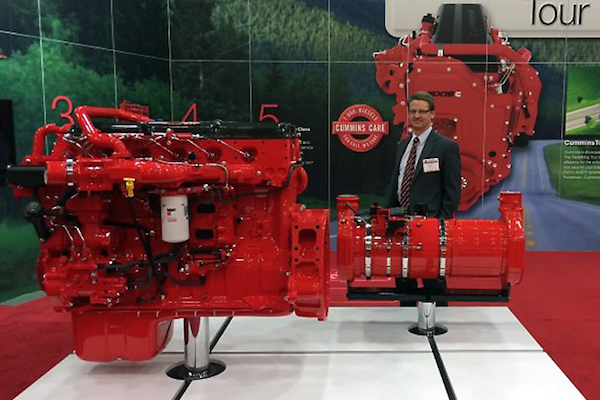

X12 Engine Sales Training EPA 2017 15 MIN. Cummins Sales and Service Learning Centers are factory authorized technical training centers for Cummins Engine and Cummins Power Generation products.

Begin Vehicle Specing in Action - Cummins Online Training New for 2020.

In this 4-hour virtual classroom session Vieth will teach you all about the operation control strategies and diagnostic procedures from 2004 through 2017. Exhaust Gas Recirculation EGR Variable Geometry Turbocharging VGT Fuel and Control Systems. X12 Engine Sales Training EPA 2017 15 MIN. At the end of the course take the quiz and you will then have the option to print a personalized certificate to. This audio training packaged in a Cummins-branded cardboard sleeve should be a hit with drivers fleets and owner-operators. How Cummins Single Module Aftertreatment Technology Works - YouTube. Reduces oxides of nitrogen NOx and particulate matter PM Achieves near-zero emissions. With a team of extremely dedicated and quality lecturers cummins aftertreatment training will not only be a place to share knowledge but also to help students get inspired to explore and discover many creative ideas from themselves. The content delivered will directly relate to the developments product changes troubleshooting and service procedures surrounding current diesel engine aftertreatment emission control systems used across.

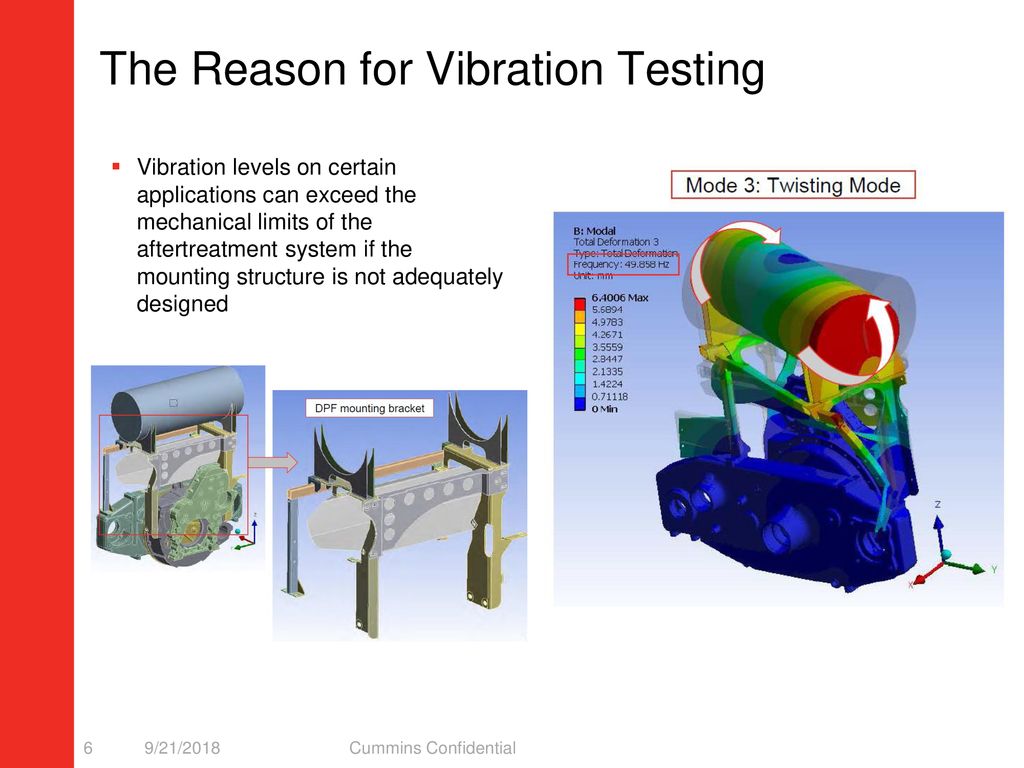

An aftertreatment system is a method or device for reducing harmful exhaust emissions from internal-combustion engines. Cummins Aftertreatment System Review. Cummins leading aftertreatment technologies are designed around proven core technologies. This includes the various sensors used such as the NOX and Particulate Sensors. With a decade of experience with oxidation catalysts particulate filters and SCR technology our aftertreatment systems help optimize your. The system is designed to operate properly in cold climates. System will provide for heating of the DEF tank by temperature controlled coolant heat.

Post a Comment for "Cummins Aftertreatment System Training"