Layered Process Audit System

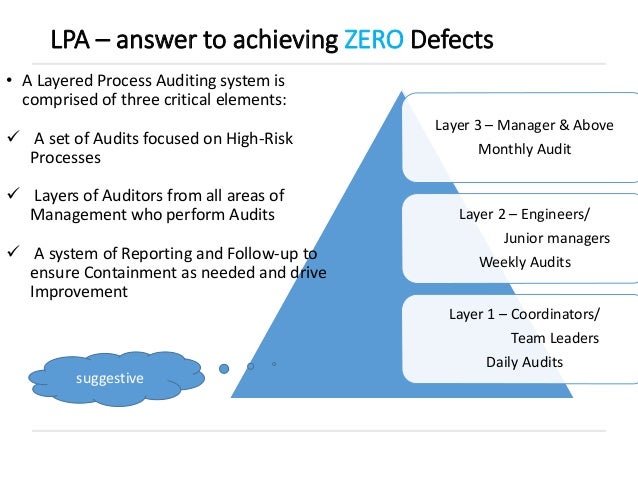

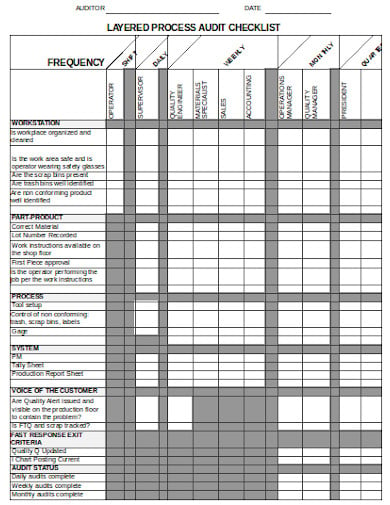

Layered process audit system. Audits can be performed by multiple levels of organization personnel including top management. Here are the 3 main components of layered process audits. The periodicity of the LPA audits is fundamental for the success of this standardization.

A global automotive supplier looking to improve visibility into quality decided to replace its manual paper-based audit system with Beacon Quality software. The LPA looks at the process elements involved in manufacturingservice delivery. A layer of auditors The goal of a layered process audit is to double-check if processes are indeed followed and ensure.

The Layered Process Audit owes its name to its working process. Now with support for 7 additional audit types. Layered Process Audits LPA is a quality tool developed for manufacturing management.

In contrast with reactive quality assurance methods that only measure outputs LPAs look at inputs like equipment materials. Buy this standard in English. The LPA scope is every.

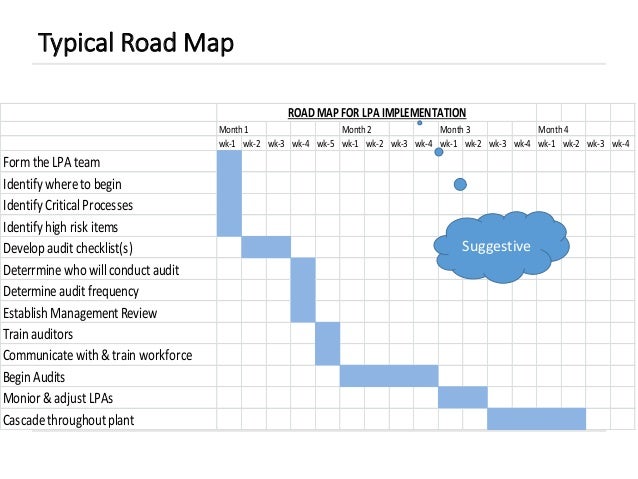

Layered Process Audit System About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features 2021 Google LLC. The basis for a successful implementation is the optimal use of time and resources within the quality team and throughout the company. A layered process audit system requires an efficient system to record and manage the data from a multistage process audit.

In order to improve the manufacturing process many manufacturers have implemented a Layered Process Audit LPA program. Buy this standard in English. Supervisors engineers managers etc LPAs are common in.

Implementing and maintaining an effective Layered Process Audit LPA program is similar to building a stool that doesnt fall over it takes three strong legs. Top Management Is Expected To Perform This Audit Also.

LPAs verify that operators are following standard procedures every shift to minimize variation defects and costs.

Realized This Requirements In 2005 Dc Cust. A global automotive supplier looking to improve visibility into quality decided to replace its manual paper-based audit system with Beacon Quality software. Implementing and maintaining an effective Layered Process Audit LPA program is similar to building a stool that doesnt fall over it takes three strong legs. Using high-frequency plant floor checks LPAs reduce process variation resulting in fewer production defects and costs while creating daily habits that build a culture of quality. Unlike other audits LPA is hosted by different hierarchical levels as Plant Managers Supervisors and Team Leaders of different areas as Production Maintenance and Supply Chain of a company. Its an ongoing chain of simple verification checks which through observation evaluation and conversations. Insight Lean Solutions also provides training for companies that want to implement effective Layered Process Audit system. Ad Process Audit - Revision 2016. Any Dc Guys On The Forum.

Supervisors engineers managers etc LPAs are common in. Top Management Is Expected To Perform This Audit Also. Layered Process Audits LPA are performed periodically and by all layers of the organization example of layers. LPAs are a sub-type of process audits that apply multiple layers of checks to process inputs known to affect quality. Layered Audits represent a formalized system focusing time and energy toward insuring high risk processes and error proofing devices do not exhibit a lot of variation and are working properly. The basis for a successful implementation is the optimal use of time and resources within the quality team and throughout the company. Best Practices for Layered Process Audit Management.

Post a Comment for "Layered Process Audit System"